Molten Metal Level Control in South Africa

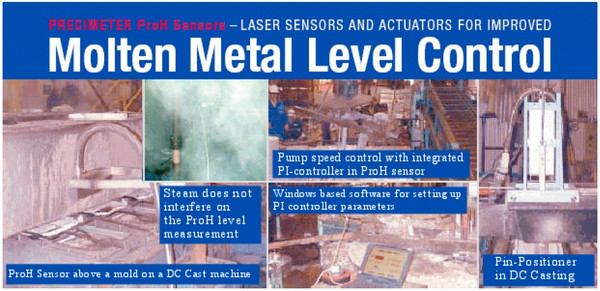

AGE Technologies has developed metal level control systems for automating the casting process of aluminium foundries. Indirect chilled molds, the metal level control consists of a laser sensor and a pin-positioner for each mold plus the PLC control system. A metal level control manufactured by AGE Technologies for certain applications consists of a laser sensor at each position. Tap-out applications consists of a laser sensor, a tap-out pin-positioner and a PLC controller. This can be integrated into most PLC or process control systems. However, you should note that the process control system must be capable of performing PID functions at a specific loop frequency.

AGE Technologies can fulfil all your Metal Level Control needs

Because of their strong technical background as a supplier, AGE Technologies is committed to provide maximum benefit to you as its customers. AGE Technologies ensures that only products of the highest quality are sold to customers. The employees working at a supplier need to upgrade their service all the time in order to stay competitive in an ever growing market. The warehouses where the metal level controls are stored cater for all necessary storage requirements.

The process of Metal Level Control

Metal level control that involves mold and head-box applications is quite a complicated process, seeing as the output of the laser sensor’s analog is connected to the input of the process control’s analog. The process control system of the metal level control controls the laser diode’s on/off power through a digital output signal to the laser sensor. This specific laser sensor comprises a digital output signal that tells the process control system that a measurement is being taken. During a the process, the laser sensor also has a temperature sensor that gives an analog signal for temperature supervision. The analog input of the pin-positioner’s controller controls the pin position. This is then operated by the plant’s PLC through an analog output. Digital inputs within the pin-positioner have digital inputs that drive the pin to a normally closed or full opened position when fully activated. This feature of the metal level control is used to calibrate the pin position to either opened or closed.

Contact AGE Technologies for Metal Level Control enquiries.